Darjeeling Tea Manufacturing

Before the tea is ready for your cup, the leaves go through the following process: plucking, withering, rolling, oxidation, drying and sorting.

Plucking is done entirely by women with their hands. It is believed that women nimble and dexterous hands will ensure that the leaves are not "injured" during plucking. It takes nearly 20000 shoots that a woman plucks to make 1 kg (around 2 lbs) of tea.

Withering is removal of moisture from the tea leaves by spreading them in a thin layer on elevated troughs. Hot and cold air is blown under the troughs. This is done for up to 20 hours to until most moisture is removed from the leaves.

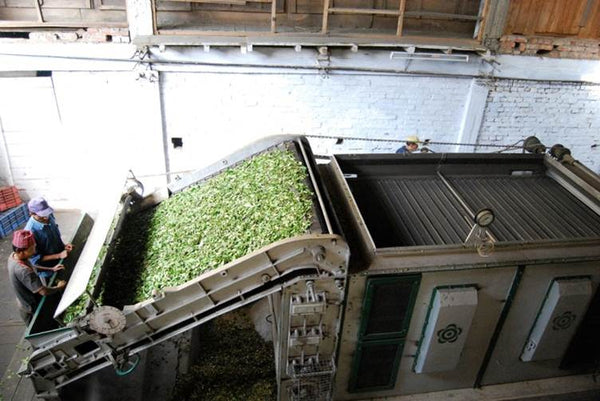

Rolling is the most mechanized part of the process where the leaves are fed in to big rolling machines which roll and bruise the leaves. The bruising exposes the cell sap, which is necessary for the oxidation process to occur. Rolling takes anywhere from 10 minutes to 50 minutes, depending upon the character of the leaf which in turn is generally determined by the harvest season.

Oxidation also known as fermentation takes place when the rolled leaves are spread on open beds where a humidity level of 80 per cent and a temperature of 70-80 F is maintained. This is the most critical step of tea manufacturing. It is a bit of science and skill where the tea maker has to be able to judge the optimum level at which to arrest the oxidation. It is this process that ultimately determines the aroma and flavor of the tea. The process itself can take three to four hours.

Drying/Firing stops the oxidation process and removes any moisture that may be present in the leaves. The fermented leaves move slowly through a drying machine where a temperature of around 250 F is maintained. It takes about 20 minutes to complete the process.

Sorting is the process to determine the various leaf grades. The dried leaves are moved over vibrating wire mesh trays. This simple apparatus sorts the leaf into whole leaf, broken leaf, fannings and dust grades.

Packing is the last step in the manufacturing process where different grades of tea are packed into plywood chests or paper sacks. Each of these packages is marked with the grade name, garden, invoice number, chest number, year of manufacture, etc.